ArcelorMittal Belgium uses cameras and AI in steel manufacturing

ArcelorMittal, the world’s leading steel and mining company, leverages Axis network cameras in combination with AI for monitoring production lines and for enhancing safety in high-risk areas. Since implementation, there has been a significant reduction in production interruptions and downtime, alongside improved safety standards and enhanced quality assurance.

Smart steel manufacturing

The ArcelorMittal Group is a leader in all major global steel markets, including automotive, construction, household appliances, and packaging, and operates in over 60 countries.

This makes the company an invisible but essential part of our everyday life, continually striving for sustainable, efficient, and reliable solutions in every aspect of its business.

ArcelorMittal is a primary driver of growth and a leading force in innovation in the steel industry.

Network cameras to monitor manufacturing processes

When ArcelorMittal Belgium sought to monitor their manufacturing processes more comprehensively and enhance personnel safety, they quickly realized that they already had the right partner at hand. The cooperation with Axis started over 15 years ago.

Combined with AI edge analytics, Axis network cameras prove to be ideally suited to these challenging industrial environments and provide the foundation for AI applications, developed by ArcelorMittal.

Today, these applications increase ArcelorMittal operational excellence, level of quality assurance, and safety while saving time and money.

Industrial environments require high quality cameras

Steel production involves intense changes in light, such as the very bright white light emitted by molten steel. This requires reliable image quality and resolution. The environment involves elevated temperatures and high‑pressure processes, within a setting that can include various operational challenges.

Therefore, cameras must be able to withstand these conditions while providing good image quality and high resolution.

Today, Axis network cameras are deployed in various applications throughout the steel production process, including the production line and ladle handling as well as final inspection and to ensure safety requirements.

Our familiarity with Axis as a company, combined with our daily experience using their products, made our decision straightforward. We require reliable, durable cameras that serve as an ideal foundation for our AI applications, and that is precisely what Axis offers.

Enhancing efficiency and monitoring of the production line

The production lines vary depending on the type of steel being produced. Across Belgium, ArcelorMittal runs seven distinct production departments - ranging from the Cold Rolling Mill to the Steel Shop, equipped with over 2,700 Axis cameras. Each line is staffed by operators at both the start and the end, with up to three operators working in cabins.

Previously, these operators had to monitor 10–20 different screens to inspect quality and production. A task that required full attention all the time, which proved to be a demanding task.

Depending on the error, operators were sometimes required to leave the cabin to assess the situation, which also required temporarily pausing the production line.

Axis cameras and AI-solution reduce human error

The objective was to alleviate workload, minimize human error in critical processes, and enable personnel to concentrate on tasks that require their expertise or physical labor.

The combination of machines and humans culminates in smart manufacturing. Based on operator feedback, Peter and his team developed an extensive AI system and new applications which greatly support operators. Consequently, traditional computer vision sensors were gradually replaced with Axis network cameras and analytics.

Now, the production lines are standardized with Axis cameras, which support operators with automated vision tools instead of manual screen monitoring.

The small, modular cameras are embedded in the machinery and equipped with intelligent analytics specifically trained to ensure that objects are correctly oriented before being maneuvered.

The AI-enabled solution supports the operators and alerts them when any anomalies are detected. If that happens, the operators decide which action needs to be taken.

Analytics ensure safe handling of molten steel

The molten metal can reach temperatures of up to 1,500 degrees Celsius (more than 2,700 degrees Fahrenheit) and is moved in huge ladles.

These ladles are suspended from the facility’s roof and lifted by cranes. Each one of them carries up to 300 tons of molten steel. Each ladle is lifted by the crane using two hooks which, when released, allow the ladle to tip forward and pour the steel into the caster.

Before the ladle is lifted, it’s essential to ensure that the hooks are properly positioned. Should the analytics detect that the hooks are not properly positioned, the process is stopped and an alert sounded, allowing the plant’s personnel to investigate the issue immediately.

Four eyes principle

The application must verify a secure ladle attachment; otherwise, the crane operator will be unable to lift the ladle, as the Safe Ladle Pickup (SLP) application interfaces with the crane's Programmable Logic Controller (PLC).

Lifting controls remain locked until the SLP application grants approval. In the event of an application issue, the crane operator can override the system only if an additional person is present on the ground to manually confirm the proper attachment of the crane hooks.

Higher reliability and safer production with AI

The molten metal is then cast into a slab of red-hot steel through a continuous caster. The slab is then cut and hot-rolled and cold-rolled into coils and plates.

This process is continuous and tightly integrated. Any issues with the process could potentially prompt a shutdown until the problem is resolved. Understandably, a shutdown has an immediate impact on the plant's output.

Therefore, real-time monitoring of the steel manufacturing process is essential for success.

Previously, ArcelorMittal Belgium employees were positioned at elevated locations to visually verify that the hooks were correctly attached. This process is now automated and monitored by an Axis block camera.

ArcelorMittal had already developed proprietary server-based analytics. The Axis custom application development team then transferred the analytics to a camera-based application. Now, with the analytics based on our open platform, ArcelorMittal can deploy it on any camera, in any facility around the world, however small.

Cameras used for weld quality inspection

Every piece of steel produced will be destined for a specific customer, from those manufacturing cars to civil engineering firms, from aerospace to consumer electronics. With an almost infinite number of sizes and grades, it’s essential that the right steel finds its way to the correct customer.

Before leaving the steelworks, Axis network cameras are employed to check each consignment of steel, checking labeling, quality of welds, such as examining that there are no cracks, contamination or porosity and even the grades of steel to ensure accuracy.

The results are clear: the quality assurance process is now more accurate and efficient.

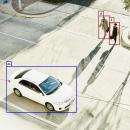

Alert for access to restricted areas

AXIS Object Analytics is used in restricted areas, triggering an alarm when individuals enter closed or restricted zones.

It is important to understand that certain areas at a steel plant can require extra attention in specific scenarios, which makes it even more challenging for technology to apply the right alarm in the right scenario.

Cameras, used as sensors via VAPIX, activate acoustic alarms and visual warnings, such as a flashing red light.

Restrictions may include not opening or standing in front of gates or doors in certain areas. At a steel production site, large machines are constantly in motion, and the areas where liquid steel is handled require particular attention due to their specific operational characteristics.

Detecting people in a restricted zone within a high-attention environment helps ensure that operations can continue smoothly and that appropriate actions can be taken when needed. Innovative technology is vital to prevent any incidents.

Ease of integration and privacy compliance

The Axis cameras and described applications are utilized in four ArcelorMittal locations in Belgium and operate nearly every day of the year. In general, Axis interfaces, the open platform and VAPIX integration enhance system operation.

The steel plant profits from the ease of integration with Axis products which is possible thanks to a stable API and the same OS across all products.

If a camera malfunctions, the company can replace it within an hour using cameras from its own stock, ensuring minimal disruption.

In some regions, legislation mandates that when surveillance technology is used for operational applications, such as process monitoring, the privacy of workers must be respected and ensured at all times. Therefore, where cameras have a broader operational view, ArcelorMittal Belgium employs AXIS Live Privacy Shield for dynamic masking of faces or even entire individuals.

Experience Center - an evolving partnership for innovation

Leveraging on Axis open platform, ArcelorMittal can deploy the AI-enabled analytics on any other Axis camera. As this transition enhances scalability and reduces infrastructure costs, ArcelorMittal aims to expand the implementation of Axis solutions globally and explore new application areas.

To facilitate this, they are creating an experience center in Belgium to showcase the use of Axis solutions, among others.

And the story goes on for smarter steel production

In Belgium, the vision AI teams meet regularly to share insights. With the benefits of the Axis solutions and analytics in process monitoring evident, there is a desire to place visual sensors more deeply into elements of the steelmaking process.

And the innovation continues, as Peter Van de Woestyne sees great potential in using AXIS Image Health Analysis to move from planned maintenance to condition-based maintenance.

Products & solutions

Get in touch

Want to know how you can benefit from Axis solutions? Get in touch and we will help you.

Contact us