Axis and Leela AI have joined forces to help manufacturers unlock hidden capacity and improve on-time delivery. Leela AI transforms Axis cameras into intelligent manufacturing data sensors, giving teams the ability to measure, compare, and analyze production in real time. Leela delivers the visibility needed to make informed decisions across manufacturing operations.

How it works

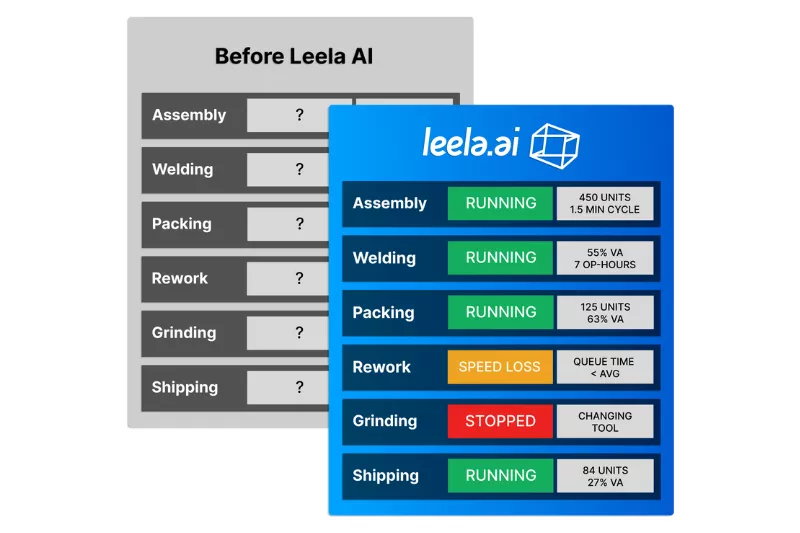

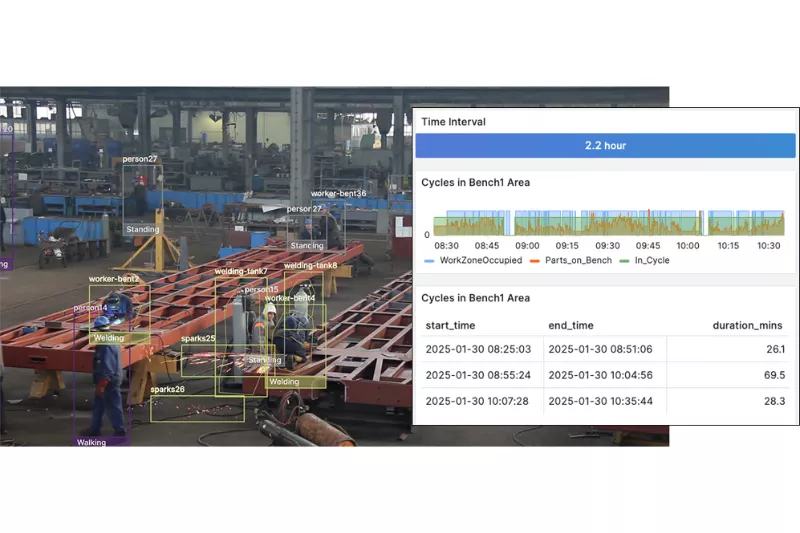

Leela AI integrates seamlessly with Axis cameras to transform video into real-time production data, without adding new sensors to equipment or disrupting operations with data entry. Using computer vision and AI, Leela tracks cycle times, material flow, labor activity, and downtime across the production floor. Intuitive dashboards provide visibility into key metrics like value-added time, line efficiency, and replenishment patterns. Teams can review historical footage, compare shift performance, and spot inefficiencies as they emerge. By automating data collection and analysis, Leela eliminates the need for manual tracking and enables faster, more informed decision-making across operations.

Why Axis and Leela AI?

Use cases

Explore Leela AI and Axis solutions

Maximize Throughput with Your Current Team and Tools

Leela AI helps manufacturers get the most from existing machines, tools, and staff by providing real-time visibility into cycle times, bottlenecks, and workstation activity. Teams can spot slowdowns early, compare shift performance, and make adjustments mid-shift to stay on track.

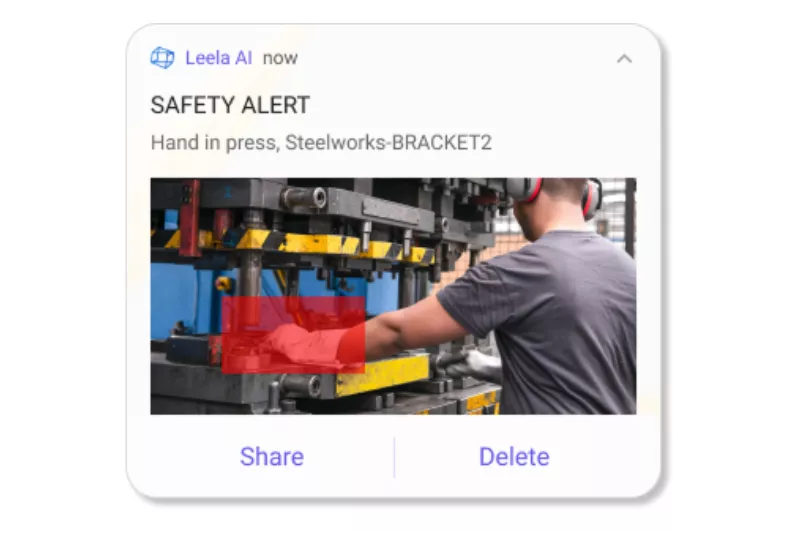

Context-Aware PPE Monitoring and Alerting

Leela AI tracks near misses and minor safety violations, such as missing face shields during grinding, to help teams identify patterns before they lead to injuries. By understanding when and where protection is required, Leela enables proactive safety enforcement and more targeted coaching.

Build a Visual Audit Trail for Every Work Unit

Leela AI creates a searchable, time-stamped visual history of production activity. This gives manufacturers the ability to trace what happened on the floor for any part, shift, or station. Whether resolving a quality issue or proving process adherence, Leela provides reliable ground truth. Teams can also analyze data by workstation, shift, or line to identify trends, set benchmarks, and track improvement.