Video surveillance and packaging: an integrated intelligent system of video cameras to increase production efficiency.

An integrated end-to-end system for advanced video surveillance and video analysis aimed at identifying malfunctions and improving production performance.

Mission

Comitel, a system integrator with 30 years’ experience took on a very ambitious challenge in responding to the needs of their client Senzani Brevetti, an Italian company specialized in the production of machinery and technology for automatic packaging systems.

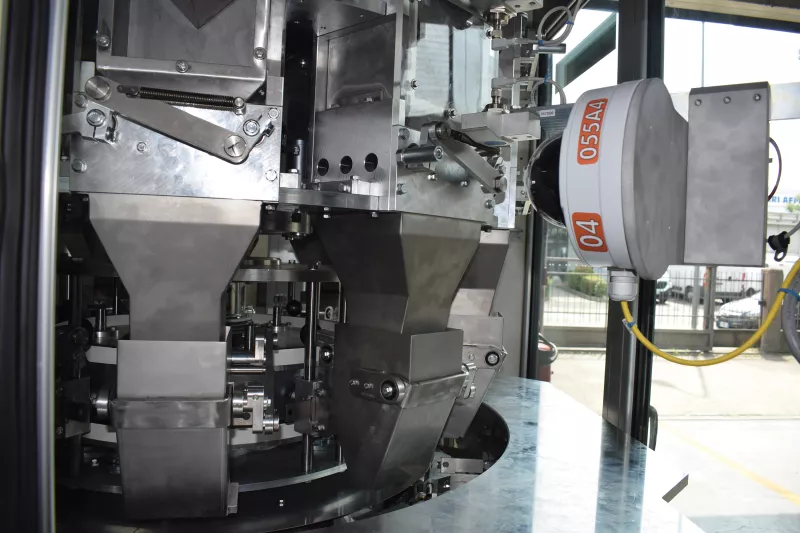

The prime requirement for Senzani Brevetti was to install a video-surveillance system in their client’s packaging plant with the aim of providing constant and continuous monitoring of the functioning of machinery equipped with very fast-rotation mechanisms. Another requirement was the possibility of being able to study recordings at any moment in order to identify problems emerging during production. As the plant in question works at very high speeds (240 packages per minute), it was in fact hard to understand at which point a malfunction had occurred with the naked eye. It was therefore necessary to identify a solution that allowed for advanced and continuous monitoring even in the absence of production control staff, in order to be able to identify the event and analyze it.

Solution

In order to respond to the requirements of Senzani Brevetti, Comitel studied an intelligent monitoring system based on the implementation of an integrated Axis solution customized according to client requirements and with a user-friendly interface. With the help of Senzani Brevetti, eight points in the plant were identified for control, integrating, for each of the points, eight IP cameras AXIS Q3515-LVE with an elevate frame rate (100 fps) and a server that stores the video recordings for 7 days (in compliance with privacy regulations).

In the proximity of these eight monitored points, it was possible to both generate alarms in the event of anomalies and map malfunctions within the timeline over which each video camera recorded, using tags (or bookmarks) to identify each event. By isolating individual frames without having to analyze hours of recordings, the identification of any anomalies has been rendered simple and rapid. This improvement was also made possible thanks to the collaboration of technology partner Milestone and their Xprotect® VMS platform.

Result

There were various advantages gained by the client with the adoption of this solution, all of which translated into an increase in efficiency and productivity from the plant. In fact, this solution requires the presence of just one operator who, via a monitor positioned externally on the machine, can check that the plant is functioning properly in real time.

Being able to analyze the exact frames showing anomalies helps to reduce costs and time spent in the event of breakdowns, with a consequential increase in efficiency from a maintenance point of view. Furthermore, in the event of the machine being opened to allow an operator to intervene, video recording and image broadcasting is suspended in order to respect the privacy of the operator in question.

In order to respond to our requirements and those of our client, we sought out solutions that delivered very high levels of performance. In this case we have 100 frames per second, the minimum necessary to be able to have a suitable level of detail, and a system of video cameras that allows continuous recording for at least 7 days. Thanks to the solutions offered by Axis and its partner Milestone, we were able to satisfy both requirements.

This project provided the system integrator Comitel with an opportunity to offer the market highly customized video surveillance solutions in which differing systems and technologies are able to communicate and integrate with each other in order to provide as exhaustive responses as possible to client requirements.

“The system integrator carried out detailed studies in designing the system in order to allow integrated communication between all components. The biggest challenges did not in fact lie in the individual solutions and technologies, but in bringing it all together, managing to best respond to all the client’s requests. This is a complex yet fruitful manner of operating, and it is the direction that the company has chosen to take,” says Luca Boschetti, Head of Design Comitel Srl.

High levels of customization and integrability are the distinctive elements that form the cornerstones of the Axis and Milestone solution designed and implemented by the system integrator Comitel for the company Senzani Brevetti, not only aimed at increasing the production efficiency of the system, but also at reducing personnel costs and simultaneously responding to important aspects regarding the protection of privacy. “It is certainly unusual to use video surveillance cameras in industry. In fact, the monitoring of processes requires high-performance video cameras that are usually very expensive and restricted in their range of use.

Thanks to the flexibility and high levels of technology offered by Axis solutions, we were able to successfully apply our video surveillance cameras to this case, as their high levels of performance are adaptable to a range of differing contexts such as industry. By offering a very user-friendly client interface and with the support of the professionalism of Senzani Brevetti, we were able to create a highly customized solution for Comitel,” stated Pierluigi Marana, KAM North East Italy.

Products & solutions